LT5.10 LASERTUBE

- Make accurate time and cost estimates.

- Prepare work orders and send them to the machines.

- Remote Management.

- Integration with ERP system.

LT7

The fully-automatic solution that guarantees maximum productivity and fast production changes. LT7 is automatically ready for the next production batch. At the end of each batch, the loader, spindle, steady rest and intermediate supports automatically adapt to the new section to be cut, without ever interrupting the production cycle.

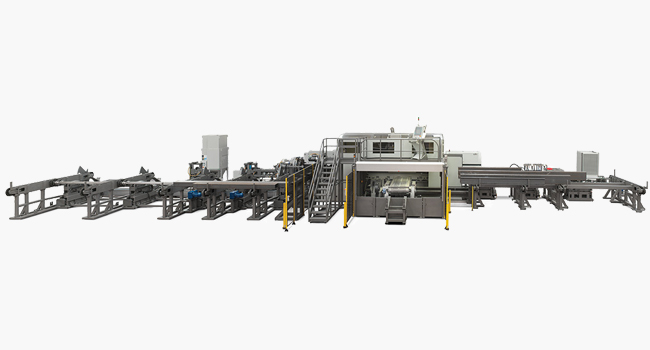

LT8.20

The solution with the widest working range in tube laser cutting. Two independent loaders that can be freely positioned at the front or rear: bundle, step-by-step, single bar. Short part unloading, scrap conveyor, motorized tables in front and rear.

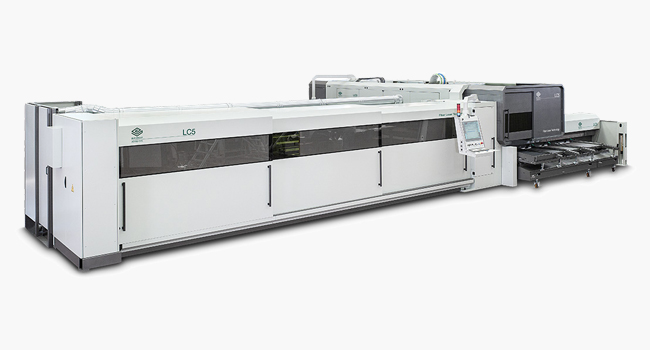

LC5

LC 5 optimally integrates two systems: a dedicated module for sheet metal cutting and a dedicated module for tube cuttiing. Switching from sheet to tube and vice versa is quick and immediate. There is no need to reconfigure or retool the machine, so you use every minute for production and optimize your investment.

LT FiberEVO

Best-in-class engineering performance, ease of use, and flexibility to process closed, open, or special shaped tubes is combined in the compact footprint of the LT FIBER EVO.

LT14

Considerably lower cost per part and improved part quality compared to other technologies (plasma, oxyfuel). The machining precision is always in line with the required tolerances and there is no need to make adjustments later, which saves time when quality is always under control.

LT24

Considerably lower cost per part and improved part quality compared to other technologies (plasma, oxyfuel). The machining precision is always in line with the required tolerances and there is no need to make adjustments later, which saves time when quality is always under control.