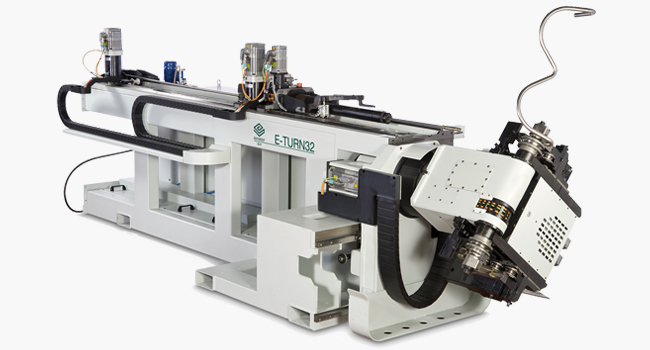

E-TURN

Because of the E-TURN’s flexibility, accuracy and peed it is often used in demanding applications such as the metal furniture industry, automotive, job shop, motorcycles and hydraulic lines for construction machinery.

The E-TURN is offered in a variety of models to process tubes up to 50.8 mm diameter E-TURN32 To 32 mm, E-TURN35 To 35 mm, E-TURN40 To 40 mm, E-TURN52 To 52 mm

- All-electric axes

- Multi-stack + Multi-radius tooling

- Right and left-hand bending in automatic cycle

- ntegrated loading & unloading

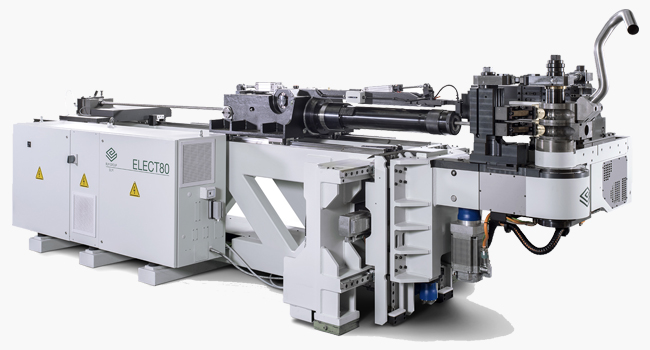

ELECT (All-Electric multi-stack CNC Tube Bender)

Efficiency : The option of adding an integrated cut off to the machine to separate multiple parts from a single bar means:

- Reduced handling

- Reduced cycle time

- Single step manufacturing

- Elimination of secondary operations which yields time, floor space, manpower and equipment savings

Capacitive touchscreen : Flat panel 19” display (16:9), multi-touch capacitive touchscreen, suitable for use even with safety gloves. Icon based user interface.

Compatible : Compatible with various CAD / CAM packages and also Compatible with ERP systems. Control features on-board.

User manual : Preventive maintenance tutorials Exploded views of machine components for spare parts identification.

4-RUNNER

The unquestionable advantage of this combined, multipurpose tube processing system is its modularity. It can be variously configured as a dedicated version for a specific job or complete process including: de-coiling, straightening, end-forming, bending, and cutting-off and unloading the finished component.

Benefits include:

- Maximum flexibility in terms of functionality and manufacturing capability.

- Maximum efficiency and lower investment costs because of process integration and just-in-time operational capability.